Pallet shrink wrap is an essential packaging material in various industries. It provides protective support for goods during storage and transportation. According to a report by Grand View Research, the global shrink wrap market is expected to reach $24.68 billion by 2025. This growth highlights the increasing demand for efficient packaging solutions.

Many businesses rely on pallet shrink wrap to secure their products. The material clings tightly when heat is applied, creating a stable unit load. However, improper application can lead to issues such as product damage. A recent industry survey indicated that 35% of companies faced challenges in effectively using pallet shrink wrap. Ensuring correct usage is vital for maintaining shipment integrity.

Despite its advantages, pallet shrink wrap faces environmental concerns. The plastic waste generated poses a dilemma for many companies. Some organizations are beginning to explore sustainable alternatives. Reflection on these practices is necessary as industries strive for balance. Addressing these challenges can pave the way for better solutions in packaging.

Pallet shrink wrap plays a vital role in logistics and material handling. It consists primarily of polyethylene. This polymer material is designed to stretch tightly around products. When heated, it shrinks, securing items on a pallet. The covering protects goods from dust, moisture, and damage. It's a simple yet effective solution for packaging needs.

The composition of pallet shrink wrap often includes additives. These can enhance properties such as UV resistance or puncture resistance. This can be beneficial for outdoor storage or during transit. While it’s an excellent protective material, it can sometimes generate excessive waste. Many companies seek to balance functionality with environmental impact. Using thinner wraps might save on material but could compromise strength. Each decision has its trade-offs.

Pallet shrink wrap has become widely adopted. However, issues like improper application can lead to problems. If not applied correctly, the wrap may not secure items effectively. This can result in shifting loads and potential damage during transport. Reflecting on these aspects can lead to better practices. Each choice made in packaging directly affects efficiency and sustainability.

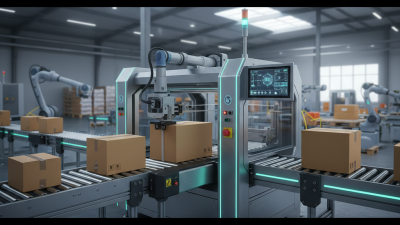

Pallet shrink wrap is essential in logistics. It covers loads tightly, protecting items during transit. This protective layer is crucial for maintaining product integrity. The wrap clings to pallets, which helps prevent shifting and damage.

Using pallet shrink wrap offers several key benefits. It minimizes dust and moisture exposure, keeping goods in prime condition. The clarity of the wrap allows for easy identification of products. Notably, it can enhance the organization of storage spaces. However, improper application can lead to wasted materials and inadequate protection.

While it provides security, there are considerations to keep in mind. The film may not always withstand extreme temperatures. Issues like tearing can occur if the wrap is too tight. It's essential to assess the quality of materials used. Additionally, the environmental impact of plastic waste deserves reflection.

| Benefit | Description | Usage in Logistics |

|---|---|---|

| Protection | Pallet shrink wrap keeps products secure and protects them from dust, moisture, and damage during transit. | Used for bundling products tightly on pallets to weather-proof the cargo. |

| Stability | Improves load stability by keeping packages together and preventing shifting. | Essential for stacking multiple pallets and ensuring safe transportation on trucks. |

| Cost-Effective | Provides a low-cost solution for securing loads compared to alternatives like wooden crates. | Widely used in warehouses to minimize packaging costs and maximize shipping efficiency. |

| Versatility | Accommodates a variety of product shapes and sizes due to its flexible nature. | Can be used in both industrial and consumer goods logistics. |

| Sustainability | Many shrink wraps are recyclable and help reduce packaging waste. | Promotes eco-friendly practices in supply chain management. |

Pallet shrink wrap is widely used in various industries for packaging and securing products. Statistics show that around 70% of manufacturers utilize shrink wrap for palletizing their goods. It provides protection against dust, moisture, and tampering. These advantages significantly reduce product damage during transportation and storage.

Efficiency is another key benefit. Studies indicate a 30% increase in productivity when using shrink wrap, due to faster packaging times. However, some companies still struggle with proper application techniques, leading to inconsistent results. Shrink wrap can rip easily if not applied correctly, which undermines its protective qualities.

Despite its popularity, many industries need to reassess their shrink wrap practices. There is a growing concern regarding environmental impact. Companies are slowly moving towards more sustainable options. Yet, many still rely heavily on traditional plastic wraps. This mismatch highlights the need for innovation and reflection on effective packaging strategies.

Pallet shrink wrap is a versatile packaging solution. It is commonly used to secure goods on a pallet, making transport safer. Different types of shrink wrap offer unique benefits. Understanding these options is crucial for effective packaging.

There are several types of pallet shrink wrap. The most common is the standard shrink film. It clings tightly around products, preventing movement. This type is ideal for most general uses. However, it has limitations in protection. It may not withstand harsh weather conditions.

Another type is polyethylene film. This wrap provides excellent puncture resistance. It is suitable for heavy or sharp items. However, its thickness can make application more challenging. A lighter film, often used for light loads, can tear easily. It’s important to choose the right type for the specific load. Reflecting on these options can lead to better choices in packaging strategies.

When applying pallet shrink wrap, it’s crucial to ensure the load's stability. Start at the base of the pallet. Wrap the film tightly around the boxes to secure them. Overlap each layer by about 50%. This method adds strength. If the wrap is too loose, it may not provide adequate support.

Be mindful of the film's tension while wrapping. Too much tension can cause the film to tear. If the shrink wrap is uneven, the load can shift during transport. It's essential to check for any gaps. Gaps can lead to damage or contamination.

Removing pallet shrink wrap requires care. Use a sharp blade, but be cautious. Cut away from yourself to avoid injury. Take your time to peel the film away gradually. This minimizes the risk of damaging the products underneath. Inadequate removal can leave bits of plastic, which is frustrating. Comprehensive attention to detail is necessary throughout this process.