In today's fast-paced packaging industry, choosing the right carton erector is crucial. The right equipment can streamline your production process and improve efficiency. A carton erector forms boxes quickly and accurately. However, making the best choice requires careful consideration of various factors.

When selecting a carton erector, think about your specific packaging requirements. Different machines cater to different needs. For instance, high-speed production lines may necessitate more advanced models. On the other hand, small businesses may benefit from simpler options. Size, speed, and production volume all play a role in determining the best fit.

It's easy to overlook these details. Many focus solely on cost, forgetting about long-term benefits. An improperly selected carton erector can hinder productivity, leading to frustration. Reflection on your unique needs is essential for making a wise decision. Prioritize understanding your workflow and operational demand to ensure optimal performance and satisfaction.

When choosing the best carton erector for your packaging needs, it's crucial to understand the available types. The market offers various models, each designed for specific tasks. For example, manual erectors can be cost-effective for small production runs. However, they may not keep up with high demands. Semi-automatic and automatic models provide speed and efficiency, essential for larger operations. According to a recent industry report, automatic carton erectors can increase production efficiency by 30% compared to manual ones.

Consider your packaging volume first. If you handle large quantities, investing in an automatic erector is worthwhile. It can significantly reduce labor costs and improve accuracy. Tips: Always assess the required speed and size of cartons. It might be tempting to choose a faster model, but ensure it fits your products.

Maintenance is another factor. Sometimes, complex machinery requires more upkeep. This can lead to unexpected downtime. A frequently neglected area in many operations is training staff on the equipment. Ensure everyone is comfortable with the machine. Tips: Regular training sessions help prevent operational errors. Reflect on past experiences. What issues arose from inadequate training? Think critically about your needs and choose wisely.

Choosing the right carton erector is crucial for streamlining packaging operations. A recent industry report noted that over 75% of manufacturers see increased efficiency with automated packaging solutions. However, selecting the best model involves key considerations.

Firstly, assess the production capacity needs. Different erectors handle various carton sizes and speeds. For example, some models can process up to 20 cartons per minute, while others struggle at 10. This discrepancy can directly impact your workflow. Additionally, consider the materials used in the erector’s construction. Durable options may cost more upfront but can lead to significant savings over time through reduced maintenance costs.

Flexibility is another important factor. Look for machines that can adapt to various carton styles and sizes. The ability to quickly switch between formats can save time during production changes. A recent analysis highlighted that companies with versatile machinery reported a 40% increase in operational adaptability. However, remember that adding features might complicate maintenance. A balance must be struck between functionality and simplicity. Always reflect on what meets your specific packaging needs without overcomplicating your process.

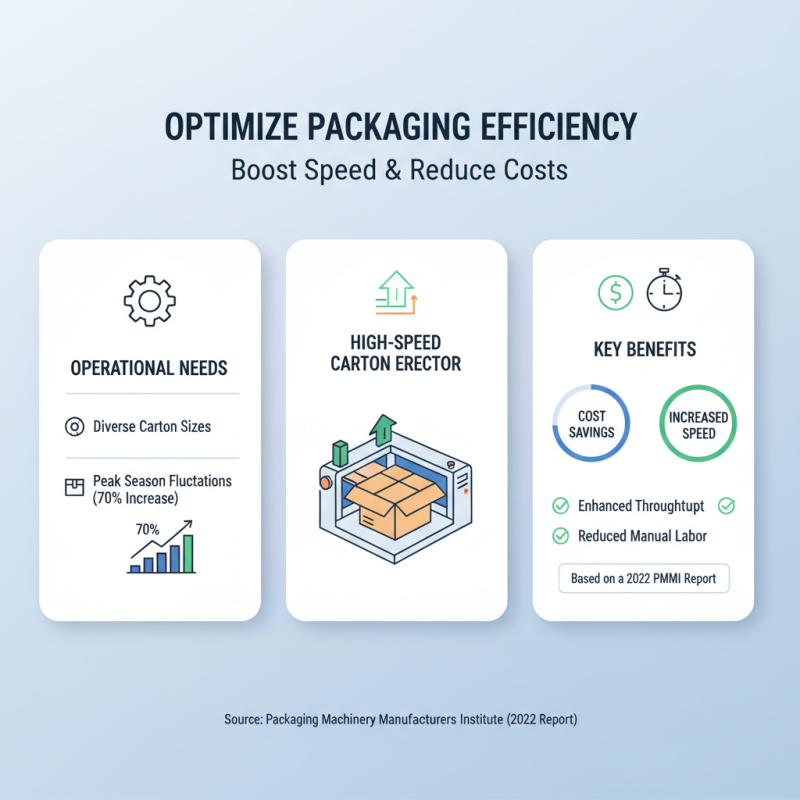

When assessing your packaging volume and speed requirements, it’s vital to understand your operational needs. Many facilities handle different carton sizes. According to a 2022 report from the Packaging Machinery Manufacturers Institute, about 70% of businesses see an increase in packaging volume during peak seasons. For these operations, a high-speed carton erector can enhance efficiency and reduce labor costs.

Speed is also a crucial factor. Some carton erectors can reach speeds up to 40 cartons per minute. However, if your volume fluctuates, a machine with adjustable speed settings may be necessary. A study by Smithers Pira indicates that 40% of manufacturers faced bottlenecks when their equipment could not keep up with demand spikes. This suggests the importance of flexibility in your choice.

Have you considered the long-term impact of your decision? Opting for a highly specialized machine may work initially. But what happens when your product line changes or demand shifts? A carton erector that adapts to varying needs could save you from investing in additional equipment later. Balancing volume and speed while remaining adaptable is essential for sustained success.

Choosing a carton erector involves evaluating various features and benefits. Key aspects include speed, reliability, and ease of use. According to a recent industry report, 70% of packaging professionals prefer machines that can be adjusted quickly for different box sizes. This flexibility saves time and increases productivity.

When exploring features, consider automation options. Fully automated erectors can reduce labor costs and minimize human error. A study found that businesses utilizing automated systems reduced their labor costs by approximately 30%. However, the initial investment can be steep. Businesses must weigh upfront costs against long-term savings.

Tips: Focus on essential features first. Look for machines with user-friendly interfaces. Ensure proper training for staff. This reduces operational mishaps and enhances efficiency.

Evaluate the maintenance requirements carefully. Some machines may have hidden upkeep costs. Regular maintenance is crucial for longevity. Neglecting it could lead to breakdowns and increased downtime. A proactive approach can save companies significant money in repairs.

| Feature | Description | Benefits |

|---|---|---|

| Automation Level | Manual, Semi-Automatic, Automatic | Increased efficiency and reduced labor costs |

| Speed | Cycles per minute (CPM) | Higher output, less downtime |

| Adjustment Features | Tool-less adjustments for different carton sizes | Flexibility to handle various product types |

| Durability | Heavy-duty construction materials | Longer lifespan and reduced maintenance costs |

| Integration | Compatibility with existing packaging lines | Seamless operations and only one system to manage |

| Safety Features | Emergency stops, safety guards | Protection for operators and compliance with safety standards |

When budgeting for a carton erecting machine, understanding costs is essential. Prices can vary significantly based on the machine's features and capabilities. Assess your production needs. A more expensive machine may offer better efficiency, leading to potential savings over time.

Consider the size of your production runs. If you're doing high volumes, the initial investment might pay off quickly. Analyze your current processes. A machine that slightly increases speed can significantly enhance productivity. Think about maintenance costs too. Frequent repairs can eat into your savings.

**Tips:**

Invest in training for your staff. Proper use reduces errors and downtime. Explore reselling options of older machines. This can offset initial costs. Don't neglect ROI. Understand how the equipment pays for itself in the long run.