Choosing the right belt conveyor can significantly impact your business operation. This decision requires careful consideration of various factors. A belt conveyor not only moves materials but also affects efficiency and productivity.

When selecting a belt conveyor, think about the type of materials you'll handle. Different materials require different conveyor designs. It’s also vital to assess the layout of your workspace. Limited space may restrict the choice of equipment.

Another aspect to ponder is the conveyor's capacity. How much weight will it carry? Misjudging this could lead to operational failures. Don't forget maintenance costs, either. A conveyor that seems cost-effective might have hidden expenses. Remember, the best choice isn't always the obvious one. Reflect on your unique needs before making a decision.

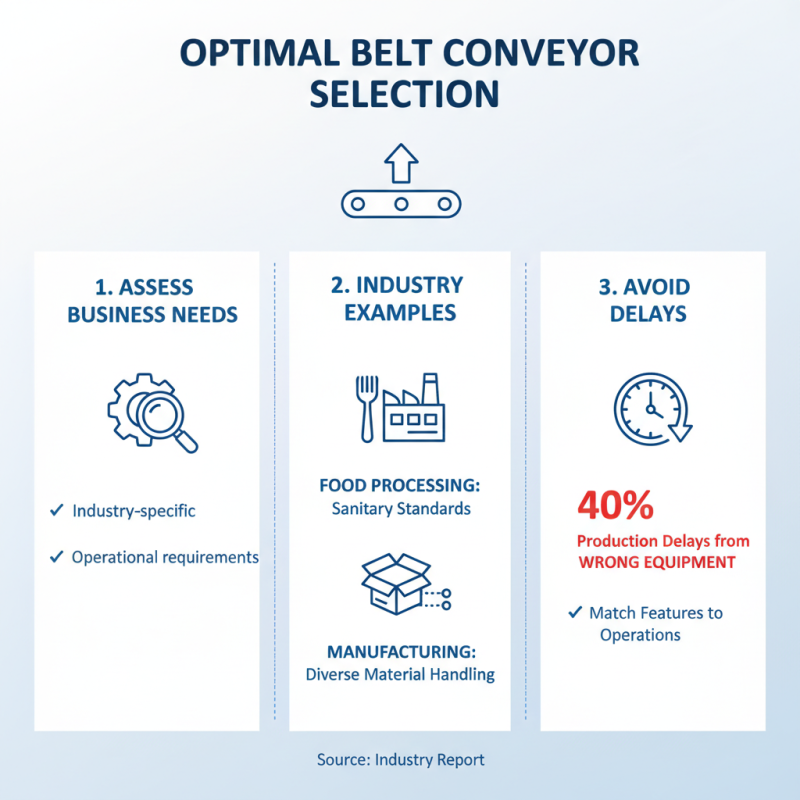

When selecting a belt conveyor, understanding your business needs is crucial. Different industries have unique requirements. For instance, the food processing sector may need conveyors that meet sanitary standards. According to a recent industry report, 40% of production delays stem from improper equipment choices. This statistic emphasizes the importance of aligning conveyor features with your specific operations.

Consider the materials you will transport. Are they bulky or fragile? The weight capacity is vital. For example, a heavy-duty conveyor might be necessary if you're moving large components. An analysis from the Conveyor Equipment Manufacturers Association indicated that conveyor failure costs businesses an average of $10,000 per hour. Therefore, it’s essential to evaluate the durability of the conveyor system based on your load types.

Evaluate the layout of your facility as well. A custom conveyor design may be more effective than a standard one. Space constraints can limit your choices. Ensure the conveyor's path fits well within your operational space. Customers have reported misalignments that caused production slowdowns. Tracking your specific workflow can help prevent this. Each decision you make should reflect careful consideration of your business's unique demands.

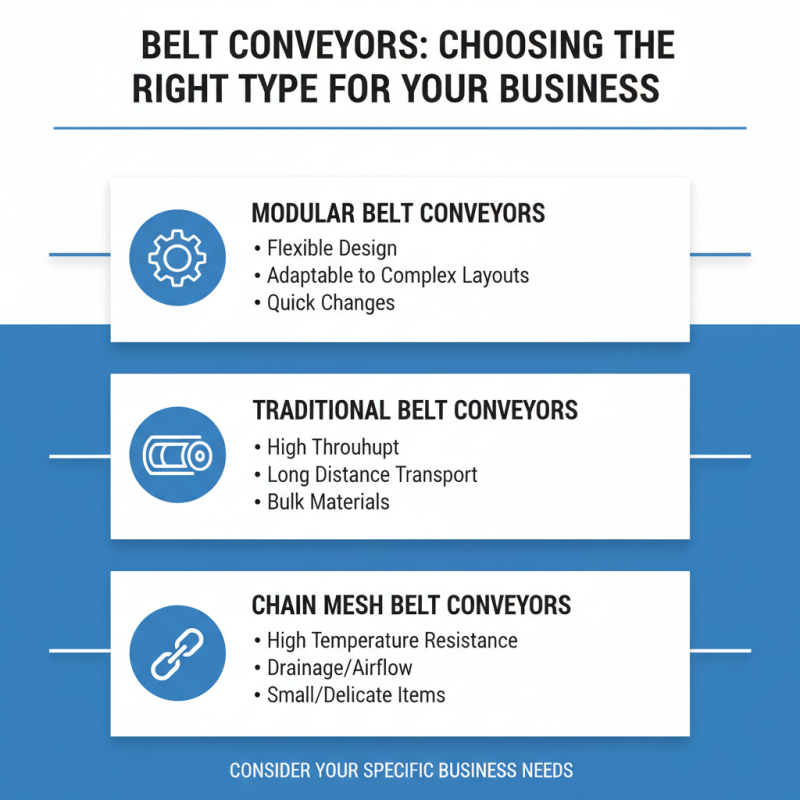

When evaluating different types of belt conveyors, consider the specific needs of your business. There are various options available, each with distinct features. For instance, modular belt conveyors offer flexibility in design and can easily adapt to complex layouts. They are great for projects that require quick changes.

On the other hand, heavy-duty belt conveyors are suitable for transporting bulk materials. These systems are robust and built to endure harsh conditions. However, their installation may require more effort and investment. Take the time to weigh how each type impacts your workflow.

Also, think about maintenance needs. Some belt conveyors demand frequent inspections, while others are more forgiving. It's easy to overlook this aspect, but it's vital for long-term efficiency. Choosing the right belt conveyor requires careful consideration of these variables. Balancing efficiency with cost is no small feat. Make sure to analyze all available options before making a choice.

When selecting the right belt conveyor for your business, several key features must be evaluated. These features ensure the conveyor meets operational needs effectively. The material type, width, and length are critical considerations. According to industry reports, around 30% of operational inefficiencies stem from inappropriate conveyor choices. Businesses should assess their workflow and choose conveyors that align with specific tasks.

One important tip is to consider the conveyor's load capacity. Industry standards report that overloading can shorten the equipment's lifespan significantly. This might lead to increased maintenance costs. It’s essential to calculate the maximum load accurately before buying. Understanding the material handling process helps in this assessment.

Another feature to think about is the belt type. Different materials provide various grip and friction levels. A flexible design can accommodate diverse applications. Nevertheless, some companies overlook the need for adaptability. Choosing a fixed design may lead to inefficiencies as operations evolve. Keeping flexibility in mind can enhance productivity over time. This proactive approach can save time and costs in the long run.

When selecting a belt conveyor, understanding load capacity and dimensions is crucial. Each conveyor has specific load limits. Choosing one that can't handle your product's weight may lead to malfunction. According to the Conveyor Equipment Manufacturers Association, overloading is a common cause of conveyor failures.

Dimensions matter too. The width and length should fit your facility's layout. A conveyor that's too wide can create unnecessary space issues. If it's too narrow, it might not meet your transport needs. It's noted that a well-fitted conveyor can enhance efficiency by 15% or more. However, a mismatch can waste time and energy.

Consider the material type as well. Different products require varied belt types. Sometimes, a standard belt isn't enough. For instance, heavy-duty items may need reinforced belts. Don't ignore these factors. Underestimating load capacity and dimensions often results in costly adjustments or replacements.

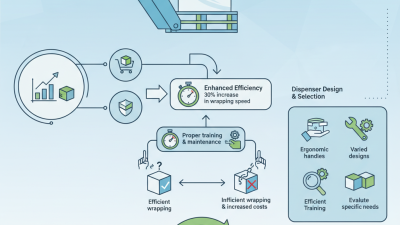

When investing in belt conveyors, maintenance and support are crucial for longevity. Reports show that proper maintenance can extend a conveyor's life by up to 30%. Regular inspections can catch small issues before they escalate. However, many businesses overlook this critical aspect.

Tip 1: Schedule frequent maintenance checks. A good rule is to inspect your conveyor at least once a month. Check for belt wear, alignment, and any unusual noises. These checks save costs in the long run.

Training your team on basic repairs is essential too. Many technicians can quickly resolve minor issues. Still, some companies find it challenging to foster a culture of proactive maintenance.

Tip 2: Evaluate your support system. Ensure that you have reliable access to technical assistance. A quick response can reduce downtime significantly. Studies indicate that companies with strong support networks experience 40% less unscheduled downtime.

Finally, review your warranty and service agreements. Know what they cover. Some contracts may provide limited support, leaving you vulnerable. Regularly aligning your operations with maintenance practices will lead to smoother workflow and better efficiency.

| Tip | Description | Considerations | Maintenance Advice |

|---|---|---|---|

| 1. Determine the Right Width | Choose a width that accommodates your product size. | Consider product dimensions and packaging. | Regularly inspect for misalignment. |

| 2. Select the Right Material | Material affects durability and load capacity. | Evaluate environmental conditions (e.g., humidity, temperature). | Follow cleaning protocols to maintain material integrity. |

| 3. Analyze Load Capacity | Understand how much weight the conveyor can handle. | Consider peak load situations and fluctuations. | Conduct regular load tests. |

| 4. Assess Conveyor Speed | Speed affects productivity and efficiency. | Match speed with operational needs. | Monitor belt wear at different speeds. |

| 5. Consider Conveyor Length | Length impacts layout and space efficiency. | Factor in available space and route requirements. | Ensure tension is maintained along the belt. |

| 6. Evaluate Safety Features | Safety measures prevent workplace accidents. | Look for emergency stop buttons and guards. | Provide training on safety protocols regularly. |

| 7. Check for Customization Options | Customization can enhance functionality. | Identify unique requirements for your business. | Document and log all custom modifications. |

| 8. Research Manufacturer Support | Good support aids in operational efficiency. | Check response times and service options. | Establish a support contract for quick assistance. |

| 9. Plan for Future Expansion | Choose a system that can adapt to growth. | Anticipate increases in production volume. | Regularly review system capacity. |

| 10. Review Cost vs. Value | Balance initial investment with long-term value. | Consider repair costs and operational savings. | Evaluate total cost of ownership over time. |